Requirement for zinc coating

The coating of the galvanized article must fulfill the requirements of the EN ISO 1461 norm 'Hot-dip galvanizing caotings on fabricated iron and steel articles- Specifications and test methods'.

- The coating should be unbroken, free from air pockets, rough spots, 'icicles' and chips, flux or zinc ash residues.

- The total uncovered surface that needs corrective actions cannot exceed 0.5% of the total surface. A single spot without coating cannot exceed 10 cm2 and it should be corrected by Jamalex. Corrective actions need to be performed with a special chemoresistant paint pigmented with zinc powder. The corrective actions should include removing contaminants and preparing the surface ensuring proper adhesion.

- Light or dark grey spots on the coating as well as white rust on the coating cannot constitute the basis for filing a claim as long as the mininmal zinc coating thickness is maintained.

- In cold-rolled profiles there may be thicker striped spots on the surface. The coating on the seams are generally much thicker than on the rest of the article.

- Rusty liquid may pour from some joints and leaky seams

- In case of steel with inappropriate content of silicon and phosphorous, much thicker and less adhesive coating may appear. Visually, the surface may be rough, of grey or dark grey color which may turn into brownish with time.

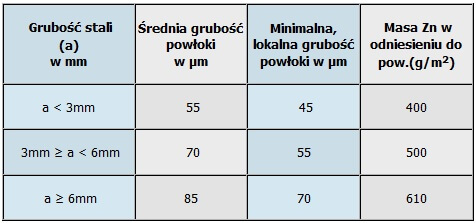

- According to the EN ISO 1461 norm the zinc coating thickness depends on the thickness.

- The layer should be flexible and well-bonded with the surface in order to sustain loading in standard usage.

- The adhesion between zinc and the surface does not need to be inspected since hot-dip galvanized zinc coatings reveal enough adhesion. After hot-dip galvanizing bending and metal forming is not advisable. ISO norms do not require testing methods to inspect the level of zinc coating adhesion to the surface.

- If the construction is to be additionally protected with paint coating, Jamalex and the Client need to agree the way of performing corrective actions between Jamalex and the Client.